Digital Twins in Industry 4.0: Bridging Physical and Virtual Worlds

In the rapidly evolving landscape of Industry 4.0, one concept is quietly revolutionizing how factories, logistics, and infrastructure are managed: Digital Twins. These virtual replicas of physical systems aren't just glorified simulations—they’re dynamic, real-time counterparts that mirror every change, stress, and operational decision happening in the real world.

🧠 What Is a Digital Twin?

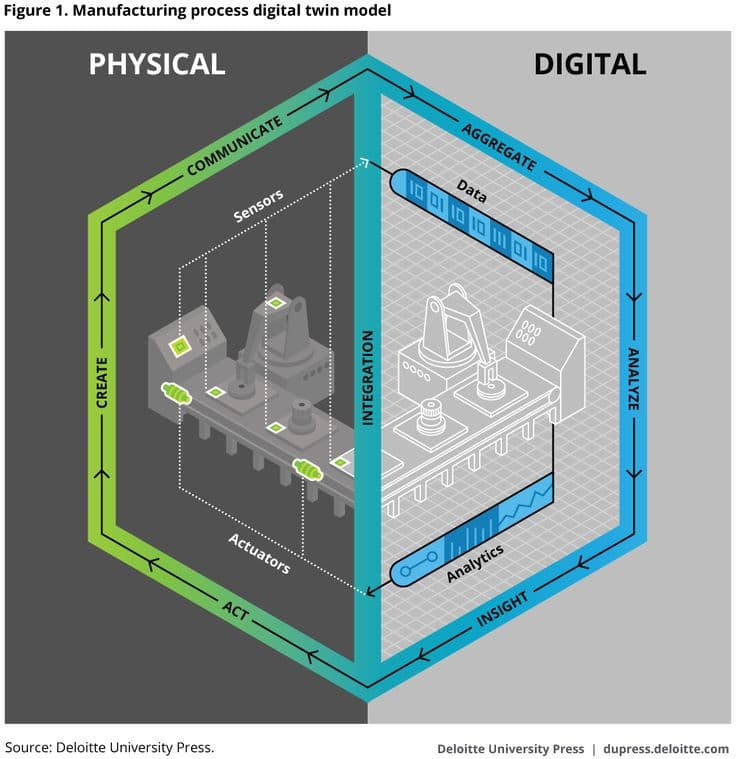

A Digital Twin is a virtual model of a physical object, process, or system. It continuously receives real-time data from its physical counterpart via sensors and IoT devices, enabling it to simulate performance, predict failures, and optimize operations. Think of it as a digital "mirror" that evolves in sync with its physical twin.

In Industry 4.0, this concept expands beyond single machines to entire production lines, logistics chains, or even smart cities.

Why It Matters in Industry 4.0

Industry 4.0 is defined by automation, data exchange, and smart manufacturing. Digital Twins are central to this vision, providing:

- Real-Time Monitoring: Operators can visualize the current state of machines and processes remotely.

- Predictive Maintenance: AI models built into the twin can forecast when components are likely to fail.

- Design & Testing: Engineers can test new configurations or materials virtually before committing resources.

- Cost Savings: Early simulations can reveal inefficiencies and optimize supply chains before problems arise.

Real-World Use Cases

- Manufacturing: Companies like Siemens and GE use digital twins to optimize turbine performance, reduce downtime, and simulate plant configurations.

- Logistics: DHL and Maersk use them to model supply chains, reroute deliveries, and minimize emissions.

- Smart Cities: Singapore has created a national-scale digital twin to simulate traffic, energy consumption, and emergency responses.

- Energy Sector: Wind farms use digital twins to model turbine behavior under different wind conditions, improving energy output.

The Future: AI + Digital Twins

The real power of digital twins is unlocked when combined with Artificial Intelligence and Machine Learning. AI-powered twins don’t just simulate reality—they predict and prescribe optimal outcomes. For example, an AI-enhanced digital twin of a factory can suggest changes in production schedules to minimize energy use during peak hours.

Challenges Ahead

While promising, digital twins require:

- Robust sensor networks

- High-quality real-time data

- Strong cybersecurity

- Cross-disciplinary collaboration between IT, OT (Operational Technology), and data science teams

Final Thoughts

Digital Twins represent a paradigm shift in how we design, operate, and optimize complex systems. As industries become more interconnected and data-driven, these digital mirrors will be key to unlocking efficiency, sustainability, and resilience in Industry 4.0.